|

Applied Microscopy. The Microscopy of Vinyl Recordings. The Elliptical Stylus and Stylus wear. |

Page 4 of 5 |

|

Applied Microscopy. The Microscopy of Vinyl Recordings. The Elliptical Stylus and Stylus wear. |

Page 4 of 5 |

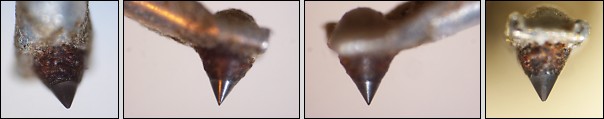

Pictured on the right is an elliptical stylus from an Ortofon FF10XE magnetic cartridge (once common on consumer-level record decks) showing the way the stylus is mounted in the cantilever

arm. The diamond part of assembly is only the conical tip. This is bonded to a metal shank which is glued into a hole made in the cantilever.

Pictured on the right is an elliptical stylus from an Ortofon FF10XE magnetic cartridge (once common on consumer-level record decks) showing the way the stylus is mounted in the cantilever

arm. The diamond part of assembly is only the conical tip. This is bonded to a metal shank which is glued into a hole made in the cantilever.

The cantilever itself is a tiny thin-walled aluminium tube which has been pressed flat at the very end (out of focus in this picture) to accommodate the stylus. The resin used to glue the stylus can be seen at the top of the picture. The stylus tip has been cleaned for this picture by careful stroking with a cotton bud moistened with saliva. The buildup of debris around the base is typical of a stylus which has been in use for some time and exerts no effect on sound or performance. The degree of wear shown in the following micrographs was sufficient to cause a slight buzzing distortion in loud passages, particularly in heavily modulated records of choral and piano music at a stylus tracking force of 1.5 grams. For less demanding recordings, no audible mistracking could be detected. The reasons for adopting an elliptical stylus profile are that whilst the broader radius across the width of the groove determines the height at which the stylus rides in the groove, as it did with the older spherical stylus, the smaller radius of that part of the stylus in contact with the wall of the groove enables more accurate tracking of the high frequency modulations of the groove. Various refinements on the elliptical stylus principle have been developed, and are well explained and illustrated in this link to the Needle Express website FAQ page. The objective of all the design types is to increase the area of contact between the stylus and the wall of the groove in a vertical direction. The high cost of these styli is a consequence of the careful grinding and polishing required to achieve the required profile, and the very exacting task of mounting the stylus in the cantilever so that the narrow axis of the ellipse is perpendicular to the line if the groove. This cost is offset somewhat by the reduced rate of wear on both stylus and records. The standard elliptical tip is made by first grinding the diamond to a conical shape having a spherical tip with a radius equal to the curvature across the major axis of the finished elliptical stylus. Narrowing the tip to form the ellipse is achieved by grinding a flat surface on the front and the back of the tip so that the profile is now "elliptical" when viewed looking directly at the tip along the axis of the cone. The front flat surface can be clearly seen in the above picture and below, far right.

Four views of the same elliptical stylus (Ortofon FF10XE): x80. In the row of illustrations above, all shot at the same magnification, the difference in stylus profile from the side and from the front can be clearly seen. The stylus is broader across the width of the groove than along its length. This observation reliably identifies an elliptical stylus. However, even when the stylus has had sufficient wear to affect its tracking in the loudest passages of the record, the change in stylus profile is almost impossible to see, even at much higher magnification. Indeed, the exact extent of stylus wear can be a difficult thing to determine regardless of the optical devices at the investigator's disposal. The challenge is to position and illuminate the stylus so as to highlight the worn areas on the sides of the stylus profile. In the pictures below, the stylus is seen from directly above with the cartridge flipped over onto its back. The first picture is lit from top and bottom, with the lights arranged to reflect in the polished surfaces formed on the sides of the stylus profile which result from wear caused by the walls of the record groove.

Left: Worn stylus showing wear surfaces from contact with groove walls.

Right: The same stylus under more general illumination. Both pics x200. L: wear caused by contact with the left-hand wall of the groove. R: wear caused by contact with the right-hand wall of the groove. Relative motion of the record groove is from right to left in both pictures. The second picture has been lit to give a general view of the stylus showing the front and rear flats which produce the elliptical shape as seen from above. The wear has occurred assymmetrically, with that part of the stylus which bears against the right-hand wall of the groove (as seen looking towards the cartridge,with the centre of the record to the left) showing more wear than the side bearing against the left-hand wall. This is probably due to the fact that the stylus cantilever has undergone a rotation in relation to the cartridge body, so that the stylus does not track the groove in a dead vertical orientation (as seen from the front). This results in a larger contact area with the right-hand wall of the groove, as can be seen from the larger area of wear. Having too high a setting of the bias (anti-skating) adjustment of the tone arm would also be consistent with this wear pattern. Since the conventions of disc recording dictate that the right stereo channel is recorded in the wall of the groove closest to the edge of the record, and the left channel in the wall closest to the centre, it is clear from the micrographs that it is the right audio channel which is being subjected to excess force. Whether the differential wear pattern seen is due to stylus misalignment or to excess bias will determine which of the two channels will provide the first audible evidence of mistracking. Even though the tracking force of the stylus above is only 1.5 grams, this force is applied to such a small area that the pressure on the walls of the groove can be surprisingly high. Measurement of the wear surfaces at higher power using an eyepiece micrometer gives a figure of 20 µm for the average width of the worn areas. Neglecting factors such as the elastic deformation of vinyl, the distribution of forces in a V-shaped groove and the accelerations at the stylus tip during tracking, simple calculation based on these figures gives a stylus pressure of 240 grams per square mm, or 340 pounds per square inch. The transient pressures exerted by a stylus tracing a heavily modulated groove during playback will of course be much greater, but beyond my ability to calculate. The pressure exerted by a new (spherical or standard elliptical) stylus is even greater than the figure calculated above, as the area of contact of the new stylus tip with the walls of the groove will be less. As areas of wear develop with use, the pressure (and therefore the damage to the walls of the groove) decreases, rapidly at first, then more slowly as the surfaces increase in area. This would suggest that really precious records should only be played with a new stylus after it has been used for a few hours to play less valuable vinyl. The need to polish a stylus in this way is much less with the special profile elliptical stylus types (Shibata, fine-line, microline, etc.) as these have already been shaped to achieve optimum contact with the groove wall. The pictures below show front and side views of an unused Ortofon OM30 stylus referred to by the makers as "nude fine line" and represents the furthest development of the elliptical stylus by this manufacturer.

As a footnote to all these observations on record wear, I have to say that of the many thousands of records which I have examined, purchased and played over the years, only a very few were unlistenable on account of record wear, and these were from the earliest days of vinyl when the manufacturers advised collectors to play them with a pickup "of not more than 8 grams" (see previous page). All other rejected discs were unplayable due to accumulated crud in the grooves and physical abuse to the record surface. I have many records which are the best part of fifty years old, and as smooth and quiet as the day they were pressed. I can only hope that my CDs last as well. Updated 8th. August, 2005. |